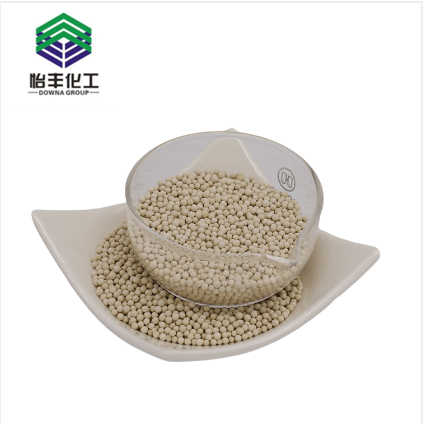

Introduction to UOP molecular sieve

UOP is a multinational company with independent technology in research and development, technology licensing, process engineering, equipment design, technical services, and the production of advanced materials, special catalysts and adsorbents.

UOP provides catalysts, molecular sieves and activated alumina for refineries, natural gas processing and petrochemical industries. It is one of the world's largest producers of catalysts and adsorbents, with an annual sales revenue of more than US $600million.

Currently, UOP manufactures about 100 different catalyst and adsorbent products for its licensed technology and other company licensed technologies,

It is used in oil refining fields such as reforming, isomerization, hydrocracking, hydrofining and oxidative desulfurization, as well as petrochemical fields including the production of aromatics (benzene, toluene and xylene), propylene, butene, ethylbenzene, styrene, cumene and cyclohexane.

UOP

It is the world's largest supplier of zeolite and aluminophosphate molecular sieves, with a production capacity of more than 63.6kt/a. It has more than 150 kinds of molecular sieves used for dehydration of gas and liquid materials in refineries, removal of trace pollutants and product separation. In addition, UOP is also the world's largest alumina producer, whose products include pseudo thin water alumina β- Alumina γ- Alumina and α- Alumina, which provides activated alumina and aluminum / silicon aluminum spherical carriers.

UOP has 11 production units in the world, which can carry out synthesis, molding, acid extraction, hydrothermal treatment, metal loading and other operations.

UOP continues to invest a lot of money in the development to scale up and industrialized the production of new materials with novel catalytic and adsorption properties. UOP uses new research tools such as combinatorial chemistry and a series of characterization methods to develop an average of 15 new industrial catalysts and adsorbents every year through pilot scale-up and industrial tests. The catalysts recently developed by UOP include r-264tm catalyst for naphtha reforming, ta-20tm catalyst for alkyl transfer of heavy aromatics, and ads-37tm adsorbent for recovery of high-purity p-xylene.

UOP

We will continue to help the global oil refining industry and natural gas industry through innovative products, excellent manufacturing and first-class technical services

The processing and petrochemical industries are facing increasingly severe challenges.